Click4.0 – Process planning with machinery supervision

Industry 4.0 and SCADA Machinery Supervision with predictive maintenance within the reach of all SMEs

PROJECT DESCRIPTION

The Click4.0 software was created with the aim of creating a new way of operating mechanical production, through innovation of the planning, execution and supervision processes of the work, through the integration of both innovative user interfaces and systems digital control of CNC machines replacing traditional interfaces with machine data. In particular, software has been created to obtain:

- Improved production planning process based on real-time data from CNC machines, resulting in:

- reduction in operating times

- drastic reduction in planning errors that cause production suspension in work centers (machines).

- Certainty of delivery of the right production instructions to the planned machine (work center), through the creation of a centralized repository of instruction files (part program), which also facilitates their possible maintenance and evolution over time.

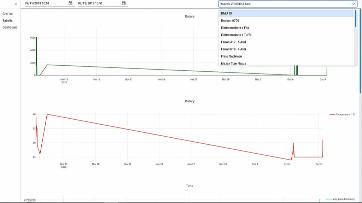

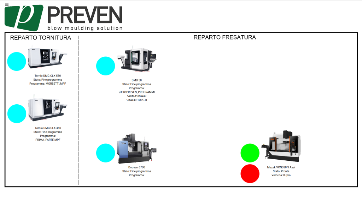

- Reduction of downtime thanks to the possibility of monitoring the production status of the machines in real time via a simple and immediate dashboard.

- Optimization of planning thanks to the availability of statistical reports on the operational efficiency of the various production machines, with data quality guaranteed by the architecture directly integrated with the microcontrollers of the numerical control machines.

- Transparent integration, i.e. simple and immediate, with the most used numerical control machines in Italy in mechanical production (CNC such as lathes, milling machines, etc.).

- Creation of a Big Data-type historical database to which intelligent analysis techniques can be applied, based on self-learning algorithms starting from historical data, with the aim of activating the predictive maintenance mode.